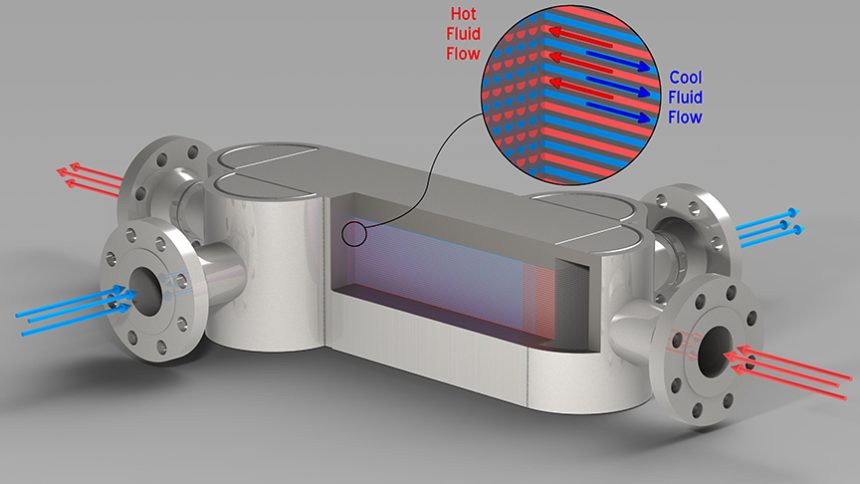

Micro heat exchanger has emerged as a revolutionary technology in chillers, and it offers greater performance, efficiency, and flexibility for countless applications of cooling. Its novel design, consisting of extremely small diameter aluminum tubes with many microchannels, offers greater heat transfer along with fulfilling the needs of modern refrigeration systems. This article describes various applications of micro heat exchangers in chillers and how they prove beneficial for increasing energy efficiency, environmental compatibility, and compliance with various industrial and commercial demands.

Applications in Commercial Chillers

Micro heat exchangers are widely used in commercial chillers, which have to supply comfortable indoor temperatures in office complexes, shopping malls, and hotels. Micro heat exchangers are employed as evaporators and condensers to facilitate efficient heat transfer between periphery air or water and refrigerant. The compact size of the micro heat exchanger reduces the volume of the chiller units, and this is particularly advantageous where the space available is limited, such as in city-centered commercial buildings.

Micro heat exchangers’ performance in heat makes commercial chillers efficient in the provision of accurate temperature control using less energy. This is crucial in large scale HVAC, where the cost of energy can quickly influence the cost of operation. Commercial chillers, by using micro heat exchangers, are capable of reducing energy consumption by as much as 25% and, therefore, become the facility’s top choice when one is looking to optimize efficiency and sustainability.

Application in Industrial Chillers

Micro heat exchangers are also vital parts in process cooling chillers used in manufacturing, food processing industries, and chemical industries. Micro heat exchanger’s ability to condense large heat load in a confined area has made it the ideal component for industrial chillers, where efficiency is required and space is limited.

For example, in beverage and food processing, micro heat exchangers enable speedy cooling of products, i.e., liquids or perishables, with minimal power expenses. The durability of aluminum composition against corrosion, typically combined with shielding layers, gives confidence of long life in severe industrial conditions in which exposure to chemicals or water is the norm. Such reliability reduces downtime as well as maintenance, resulting in overall productivity.

Integration in Data Center Cooling

Data centers, which have such high cooling requirements, are the best application for micro heat exchangers on chillers. The proliferation of cloud computing and data processing has created increased levels of demand for efficient cooling systems to maintain servers and IT gear at the correct temperatures necessary for peak performance. Micro heat exchangers enable chillers to deliver precise cooling with low energy expenditure that enables high heat loads of data center machinery.

Compact size of micro heat exchanger enables developing low-weight, low-volume chiller units to be incorporated into modular data center cooling systems. Moreover, compatibility of micro heat exchangers with low-GWP refrigerants like R32 or CO2 is enabling climate-friendly cooling solutions that fulfill the sustainability targets of numerous data center owners. Low refrigerant charge of micro heat exchangers also reduces the environmental threat posed by possible leaks.

Retrofitting Aging Chiller Systems

Micro heat exchangers increasingly are being used to retro-fit existing chiller systems for improved performance and compliance with today’s environmental regulations. Legacy chillers rely on older heat exchanger designs with large amounts of high-GWP refrigerants, such as R22, which themselves are under phase-down globally. It is possible to switch these out with micro heat exchangers and still use environmentally sound refrigerants, maximizing system performance.

Micro heat exchangers’ compactness and lightness facilitate retrofitting because they can be retrofitted into current chiller infrastructure without substantial structural changes. Retrofit facilitates the extension of chiller lifespan, reduced energy costs, and regulation compliance like the Kigali Amendment. Retrofitting with micro heat exchangers is viewed by facility managers as a financially viable way to upgrade old infrastructure.

Applications in Precision Cooling

Micro heat exchangers are of immense benefit to precision cooling facilities like laboratories, healthcare centers, and cleanrooms. Such facilities require very stringent temperature and humidity control in order to preserve the integrity of sensitive equipment or processes. The excellent heat transfer capability of the micro heat exchanger enables chillers to deliver stable cooling performance despite changing load conditions.

Micro heat exchangers, for instance, are applied in chillers utilized to cool MRI scanners and other diagnostic machines where precision control of temperature is critical. The potential to employ such heat exchangers at low refrigerant consumption with consistent performance identifies them as ideal for such critical applications, which ensure reliability and minimal wastage of energy.

Micro heat exchangers are also used in energy recovery system-integrated chillers, where heat waste is recovered and used to increase efficiency overall. Micro heat exchangers in these systems provide efficient transfer of the chiller’s refrigerant to secondary fluids such as water or air, used for energy recovery. Such an application is beneficial for very energy-efficient buildings, for instance, LEED-certified buildings.

By enabling chillers to recover and recycle heat, micro heat exchangers minimize the energy input required to heat or cool, reducing operating costs. Micro heat exchangers are small enough to easily fit in energy recovery systems with an across-the-board solution in green chiller designs.

Enabling Green Chiller Designs

Environmental advantages of micro heat exchangers include having them as a part of environmentally friendly chiller design. The lowered refrigerant charge minimizes the environmental footprint of chillers, especially in terms of greenhouse gas emissions. In addition, the aluminum composition of micro heat exchangers is entirely recyclable, hence promoting circular economy and minimizing end-of-life waste.

The integration of micro heat exchangers with low-GWP refrigerants further increases their sustainability benefits. As the worldwide regulations are compelling the applications of green refrigerants, micro heat exchanger chillers will be able to provide the same without compromising on performance. They are thus a great option for carbon-conscious companies.

Conclusion

Micro heat exchanger is a highly efficient and compact device that has revolutionized the application of chillers in industries. Applied in uses such as industrial process cooling, commercial air conditioning, data centers, retrofit packages, precision cooling, and energy recovery systems, micro heat exchangers are more efficient and effective in terms of energy utilization. Their space-saving design, compatibility with environmentally friendly refrigerants, and durability make them a technology of necessity for the chiller today. As demand grows for effective and environmentally friendly cooling products, micro heat exchangers will remain a force to be reckoned with in chiller technology.